Lockout Tags and Labels for Workplace Protection

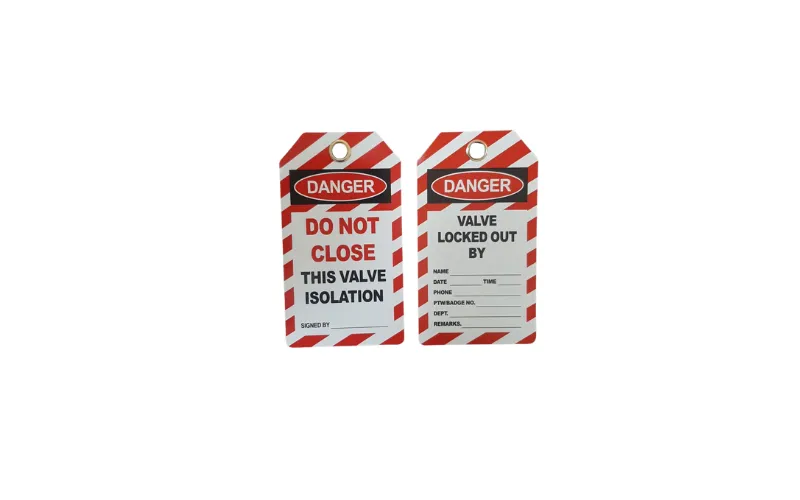

Lockout tagout tags are designed for the purpose of ensuring dangerous machines are properly shut off and keeping the machine idle and tagged during the maintenance or repair time In order to give awareness to the people.

Features of Lockout Tags

Labels and signs will help you communicate safety and lockout information at the point of need. These tags, labels and signs come in a variety of materials and are available in OSHA-compliant Lockout/tagout (LOTO) formats. It is a great way to visually provide warnings and instructions for preventing unexpected machine start-ups, and alert equipment operators about proper lockout procedures during maintenance and repair.

Products

Types of Lockout Tags and Labels

1. Safety Padlock Labels

Safety padlock labels are designed to fit safety padlocks, ensuring that workers can easily identify which machines are under lockout. These labels provide clear instructions, such as “Do Not Operate,” and help send a clear message when a machine is down for service or maintenance.

Benefits:

- Easily attachable to safety padlocks.

- Durable and resistant to wear and tear.

- Enhances visibility of locked-out equipment.

2. Lockout Tag with Detachable Key Stub

This innovative tag is made of perforated card stock and includes a detachable key stub. The matching identification numbers printed on the tag and stub make it easy to track and match padlocks with the right keys. A 10 mm diameter metal ring is provided to attach the stub securely to the corresponding key.

Benefits:

- Simplifies the lockout process by ensuring proper key matching.

- Durable construction for repeated use.

- Reduces the chances of misplaced keys and ensures accountability.

Applications of Lockout Tags and Labels

Lockout tags and labels play a vital role in workplace safety across various industries, including manufacturing, energy, construction, and healthcare. They are used in:

- Machinery Lockouts: Ensuring that equipment stays off during repairs or servicing.

- Electrical Systems: Identifying circuits or panels undergoing maintenance.

- Valve Lockouts: Tagging valve handles to alert workers about locked-out pipelines.

- Hazard Communication: Informing workers about potential dangers and proper safety protocols.

Why Choose Lockout Tags and Labels for Workplace Protection?

- Enhanced Safety: Lockout tags and labels provide a visible and durable solution for maintaining safety protocols.

- Regulatory Compliance: They ensure adherence to OSHA and other industry safety standards, reducing the risk of non-compliance penalties.

- Cost-Effective: Preventing workplace accidents can save costs associated with medical expenses, equipment damage, and downtime.

- Efficiency: Streamlined processes such as key identification and visual communication improve overall workplace efficiency.

Why Choose Lockout Tags and Labels for Workplace Protection?

| Type of Lockout Tagout Tags | Description | Applications |

|---|---|---|

| Mechanical Lockout Tags | Tags designed for locking out mechanical equipment, such as machines, valves, and moving parts. | Used during maintenance or repair of mechanical systems to prevent accidental start-ups or movement. |

| Electrical Lockout Tags | Tags specifically made for electrical systems to indicate circuits, breakers, or equipment under lockout. | Applied to electrical panels, circuit breakers, and other electrical components to ensure safety. |

| Operation Lockout Tags | Tags used for operation-specific lockouts to indicate ongoing maintenance or restricted access. | Ideal for operational machinery or areas requiring restricted access during specific tasks or servicing. |

| Instrument Lockout Tags | Tags used to lock out precision instruments and sensitive equipment to avoid accidental usage or calibration. | Commonly used in labs, testing facilities, and industries relying on calibrated instruments. |

| General Lockout Tags | Multipurpose tags for general lockout applications, ensuring compliance and safety in various scenarios. | Used across industries for tagging tools, equipment, or systems requiring lockout during servicing. |